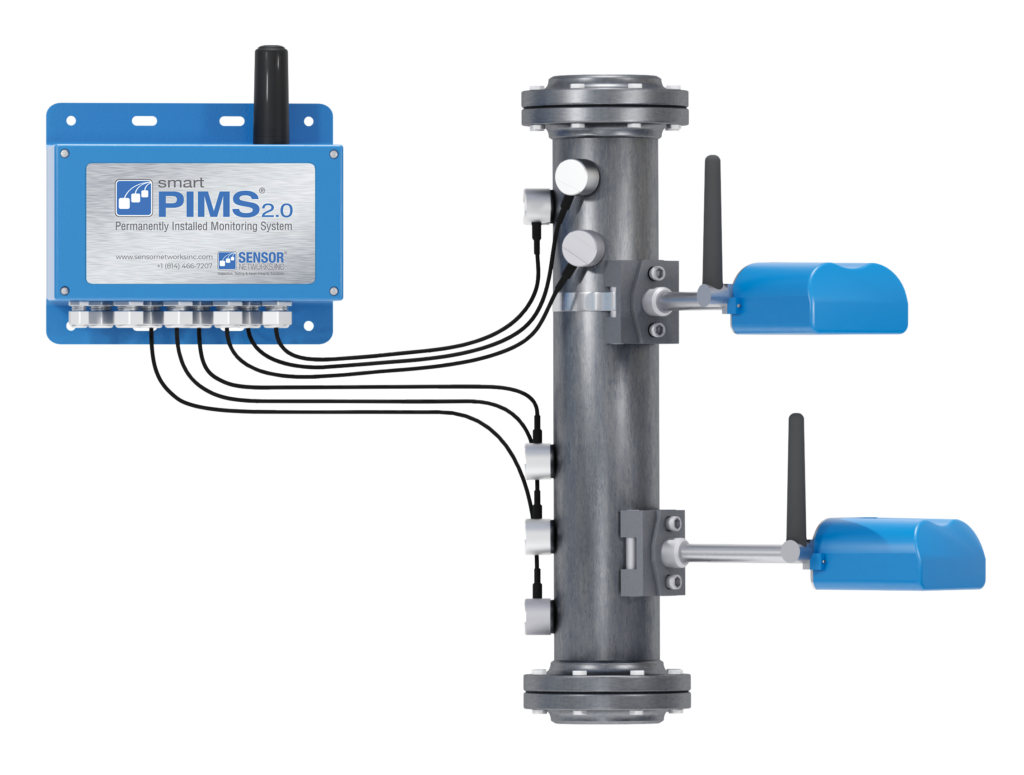

Metal-loss monitoring is essential to maintaining the safety and integrity of various types of infrastructure, including pipelines, tanks, and other metal structures. Traditional methods of metal-loss monitoring involve regular physical inspections or intrusive monitoring systems that require cutting into the metal surface. However, there is now an alternative solution that provides accurate, real-time monitoring without damaging or altering the material being tested: Remote Non-Intrusive Metal-Loss Monitoring using Installed Sensors.

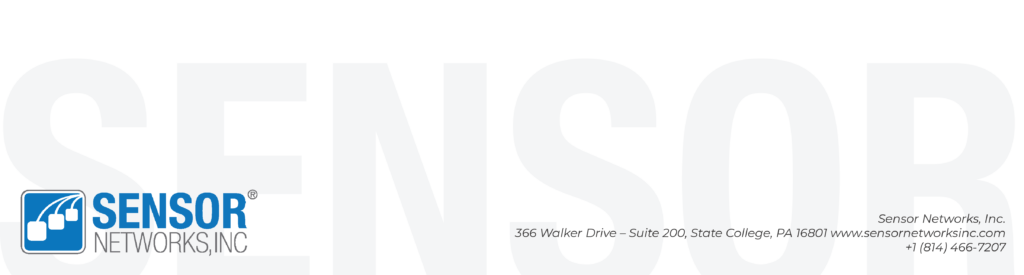

Sensor Networks, Inc. is at the forefront of advanced monitoring technologies, utilizing non-intrusive installed ultrasonic sensors that can accurately detect and monitor metal loss and flaw growth in a variety of settings.

Why installed sensors

Data Fidelity & Integrity

Installed Sensors provide for a much higher quantity and quality of the measurement data along with exact traceability of the date, time, location, temperature, and the raw signal’s RF waveform.

Data Privacy

Sensor Networks’ non-intrusive monitoring systems are designed to integrate into your private networks and backend systems. Wired systems connect directly to a pc or Modbus network to provide an alternate level of security for your critical data. We also offer a PW-protected AWS cloud solution for remote data access and analysis. This cloud solution ensures the security and privacy of your critical data, while also allowing you the convenience of accessing and analyzing your data remotely, from anywhere, and at any time.

Safety

Permanently or temporarily installed non-intrusive UT sensors allow for data collection without manual inspection. Once installed, the sensors can be left in place for extended periods, providing continuous monitoring This keeps personnel from needing to go to, travel to, and work in hazardous areas including ATEX Zone 0 atmospheres or the exposure to intrusive sensor maintenance.

Superior Measurement

With an industry-best performance, Sensor Networks’ dual-element UT corrosion sensors can measure down to < 0.040 inches (1mm), a capability not achieved with any other corrosion monitoring systems. The two measurement sensor models are paired with a temperature sensor for compensation calculation.

The versatility of installed sensors

Upstream Oil & Gas

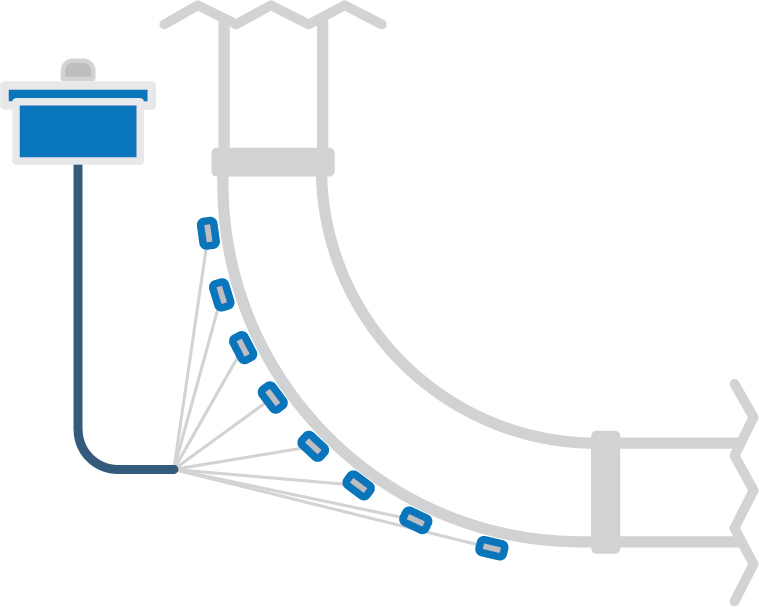

Multi-point monitoring for sand erosion on elbows is used to assess the level of metal-loss-related erosion on the ID of elbows of pipelines in the oil and gas industry. Sand erosion is a common problem in pipelines that transport crude oil or natural gas containing sand and other abrasive particles.

Multi-point monitoring systems are installed on the elbows of the pipeline to measure the level of erosion. A series of ultrasonic sensors are strategically placed around the elbow to provide a comprehensive picture of the erosion patterns.

Midstream Oil & Gas

In midstream applications, above-ground and buried pipelines are often exposed to environmental factors that can lead to corrosion. To prevent this, multi-point and area monitors can be used to detect the presence of corrosion and other potentially damaging conditions.

Downstream Oil & Gas

Downstream monitoring using installed sensors is an effective method for ensuring the integrity and reliability of critical assets in various industries.

- 1. General corrosion monitoring

- 2. Process control optimization

- 3. IOW and FFS (fitness for service) for critical asset monitoring

- 4. Chemical inhibitor verification

- 5. Unmanned data collection for difficult-to-reach or hazardous areas

Power Gen

Power generation facilities rely on critical equipment to ensure smooth operations, and utilizing installed sensors for monitoring is a cost-effective and efficient way to ensure the reliability and safety of that equipment.

- 1. Gas void detection (GAMP) in nuclear power plant service water & cooling pipes

- 2. Flow-Assisted Corrosion (FAC)

- 3. Critical Asset/High Energy Piping

- 4. Areas with high radiation

Renewables

One of the key challenges in renewables is monitoring the critical metal or composite rotating components for defect or crack propagation, typically in areas that are difficult for manual inspections.

- 1. Shaft crack monitoring

- 2. Critical blade monitoring

- 3. Barrel nut monitoring

- 4. Splash-zone corrosion monitoring

Mining

Sensor Networks, Inc. provides monitoring solutions that can help mining operations detect and prevent damage to critical assets, improving efficiency and reducing maintenance costs.

- 1. Erosion monitoring on long-radius piping bends; buried and above-ground slurry lines

- 2. Corrosion monitoring of assets at mining refineries and facilities

Remote non-intrusive metal-loss monitoring using installed sensors provides a cost-effective and efficient solution for ensuring the safety and reliability of critical infrastructure across various industries. With the versatility of installed sensors, our solutions can be applied in upstream, midstream, downstream, power generation, renewables, and mining applications to monitor erosion, corrosion, critical components, and other potentially damaging conditions. The use of installed sensors is not only cost-effective but also promotes safety, making it an indispensable solution for those seeking to improve operational efficiency and reduce maintenance costs.

Sensor Networks Inc. (SNI) is a U.S.-based technology company that specializes in Nondestructive testing (NDT). With dozens of experts and hundreds of years of combined NDT experience, SNI helps customers inspect their assets safely and cost-effectively. SNI has a hands-on approach and individualizes every customer experience.

To see how the SNI team can help you with your application needs, request a free consultation and HW / SW demo today!