Compared to manual inspection, ultrasonic corrosion monitoring sensors allow for a safer, cheaper, and more efficient inspection of critical assets. These wired or wireless sensors have been installed in refineries, petrochemical plants, midstream facilities for storage, transmission, and distribution, as well as power generation facilities. The ultrasonic sensors generate a corrosion rate by measuring wall thickness values over time. Using specialized software, users can trend, analyze, and set custom alerts when desired thresholds are reached. The data helps the owner’s process control and inspection teams assess risks and extend the asset’s life.

Remote monitoring sensors produced by the SNI team solve a wide range of applications in the oil and gas, power gen, and mining industries. Once installed, the sensors can monitor suspected areas of internal corrosion or erosion temporarily or permanently.

Dominion Transmission, Inc. (DTI) of Central Pennsylvania is one of many companies using SNI’s technology for their midstream applications. When DTI conducted their current inline inspection (ILI) report, they saw internal corrosion indications at two locations on their 24” natural gas transmission pipeline.

In response to these findings, DTI excavated the sites and secured a third-party vendor to perform digital X-ray and ultrasonic C-scan mapping on the affected areas. An engineering assessment confirmed that the pipeline was safe to operate under current operating parameters.

To proactively monitor these indications of internal corrosion, DTI chose to install ultrasonic corrosion monitoring sensors from SNI. Future ILI inspections will compare the ILI data to the captured from the monitoring sensors, providing another method of confirming the accuracy of the ILI assessment.

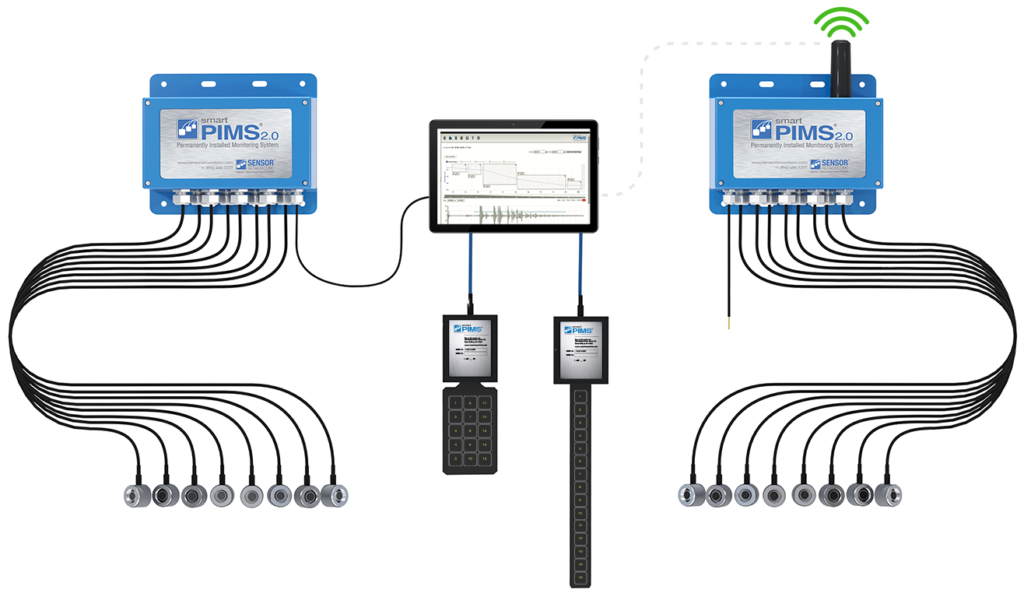

SNI sensors were permanently installed at two sites along the DTI pipeline. At the first site, a smartPIMS® Modbus system was installed with eight dual-element sensors. Site two was equipped with one smartPIMS® Modbus system with four dual-element sensors and one matPIMS™ 1×15 area monitor also connected via Modbus.

The sensors allow DTI to monitor the internal corrosion indications identified by the ILI data. A DTI Corrosion Technician will visit the site each month to download thickness data readings onto a tablet using Sensor Networks’ proprietary software, webPIMS™. The monthly wall thickness readings will determine whether there is ongoing corrosion and if so, the rate of corrosion. Using this data, DTI can ensure the integrity of the pipeline.

In response to DTI’s success with the smartPIMS Modbus, Company President & CTO Jim Barshinger said, “Sensor Networks Inc. is very pleased and proud to have this opportunity to work with Dominion and deploy our corrosion monitoring system on their infrastructure. Remotely tracking the growth of these individual pits and general corrosion rates in a buried pipeline is a perfect application for our technology coupled with remote client access to the data through our webPIMS software.”

Sensor Networks Inc. (SNI) is a U.S.-based technology company that specializes in Non-destructive testing (NDT). With dozens of experts and over a hundred years of combined NDT experience, SNI helps customers inspect their assets safely and cost-effectively. SNI has a hands-on approach and individualizes every customer experience.

To see how the SNI team can help you with your application needs, request a free consultation and demo today.