Knowing the difficulties and obstacles that come with inspecting large, confined spaces such as underground mines, SNI has crafted its Hi-Def PTZ3.0 to meet the needs of such inspections. The small, visual inspection device is a portable, Pan-Tilt-Zoom high-definition video inspection system loaded with the features necessary to inspect large, confined spaces.

When used in the setting of a mine, the Hi-Def PTZ3.0 offers the high-quality video and advanced lighting capabilities need to properly execute various inspection applications such as interrogating underground voids in mine shafts.

To look at the size and structural integrity of voids in an active mine, the Hi-Def PTZ3.0 can be inserted through an opening 3-inches or larger in diameter. In most cases, the camera is lowered down a drilled hole. It can be lowered to depths up to 500ft to look for any signs of trouble that could cause a collapse due to large vehicles and machinery overhead.

In a similar fashion, the inspection camera can be lowered down existing mine shafts to inspect the integrity of the support beams and/or find potential blockages.

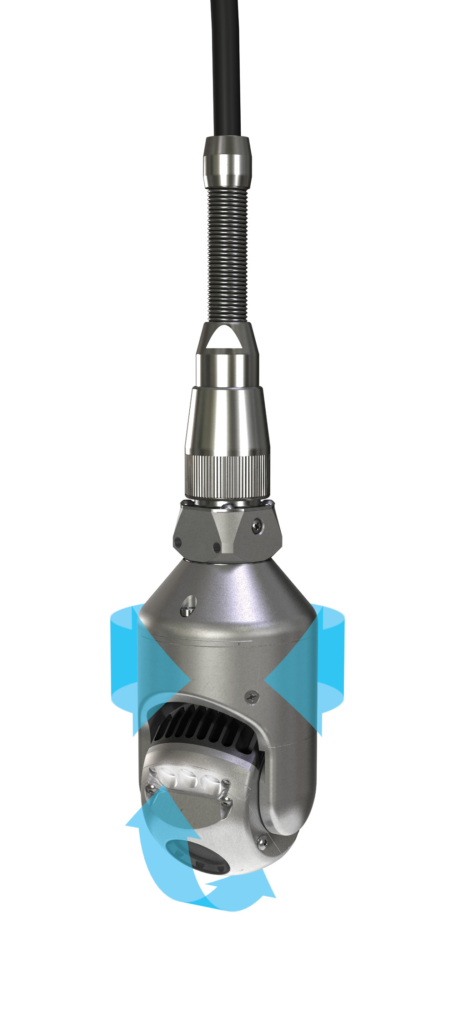

What the Hi-Def PTZ3.0 offers is high-quality, 1080P video output with built-in 1500 lumens of LED lights. All in a small, compact, sub 3-inch diameter camera head. The enhanced lighting is critical when inspecting very large, dark underground settings such as mines and helps efficiently expose and classify any hazardous issues.

The Hi-Def PTZ3.0 offers an innovative RVI solution to mine inspection that can ensure the safety of employees and equipment – saving lives and money.

Learn more about the Hi-Def PTZx

View the Hi-Def PTZ3.0 Data Sheet