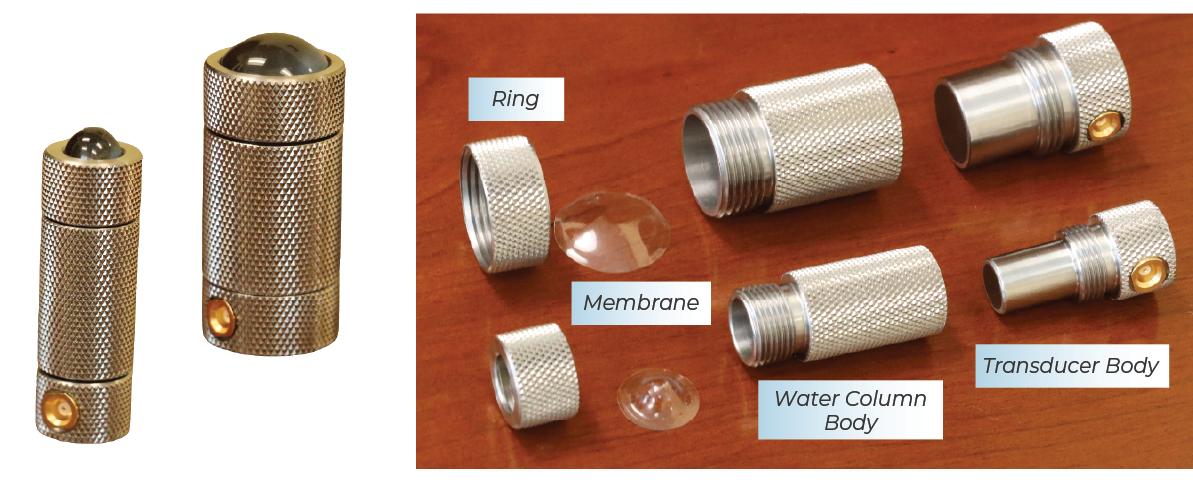

Membrane

flexible water-filled membrane transducer

Part Numbers

| Frequency (MHz) | Element Diameter | Part Number | Membranes | |

|---|---|---|---|---|

| Inch | mm | C Series | ||

| 1.5 | 0.25 | 6.4 | 00-013863 | See Membrane Chart |

| 0.50 | 12.7 | 00-013866 | See Membrane Chart | |

| 2.25 | 0.25 | 6.4 | 00-013864 | See Membrane Chart |

| 0.50 | 12.7 | 00-013867 | See Membrane Chart | |

| 3.5 | 0.25 | 6.4 | 00-013865 | See Membrane Chart |

| 0.50 | 12.7 | 00-013868 | See Membrane Chart |

Case Dimensions

Case dimensions coming soon

| Part Number | Fits | Thickness | Material | Characteristics |

|---|---|---|---|---|

| (Pack of 12) | ||||

| 01-013016 | 0.25″ Element Transducer | 50 Micron (.002″) | UltraFlex | Most flexible, highly conformable, most protrusion. Recommended for static position testing due to higher coefficient of friction. |

| 01-012373 | 0.25″ Element Transducer | 50 Micron (.002″) | UltraWear | More wear resistant, medium conformability & protrusion. Recommended for scanning due to lower coefficient of friction. |

| 01-012359 | 0.25″ Element Transducer | 100 Micron (.004″) | UltraWear | Most wear resistant, less conformability & protrusion. Recommended for scanning on flatter objects, less likely choice. |

| 01-013018 | 0.5″ Element Transducer | 50 Micron (.002″) | UltraFlex | Most flexible, highly conformable, most protrusion. Recommended for static position testing due to higher coefficient of friction. |

| 01-012375 | 0.5″ Element Transducer | 50 Micron (.002″) | UltraWear | More wear resistant, medium conformability & protrusion. Recommended for scanning due to lower coefficient of friction. |

| 01-012360 | 0.5″ Element Transducer | 100 Micron (.004″) | UltraWear | Most wear resistant, less conformability & protrusion. Recommended for scanning on flatter objects, less likely choice. |

Membrane Transducers

The water-filled flexible membrane transducer maximizes the defect response on irregular entry surfaces, enhancing the ability to inspect irregularly shaped components with better penetration and resolution.

The current low-frequency models (1.5, 2.25, and 3.5 MHz) were designed to inspect carbon composite in the aerospace industry – but this technique is applicable to many other applications and materials.

The transducer is customizable for an easy and accurate inspection process. The membrane is replaceable and available in two materials – UltraFlex (for maximum conformability) and UltraWear (for maximum wear). The membrane can also be filled with water or Glycol liquid (for cold environments).

Typical Applications

- Carbon Composite Inspection

- Irregular Shapes & Surfaces

Series

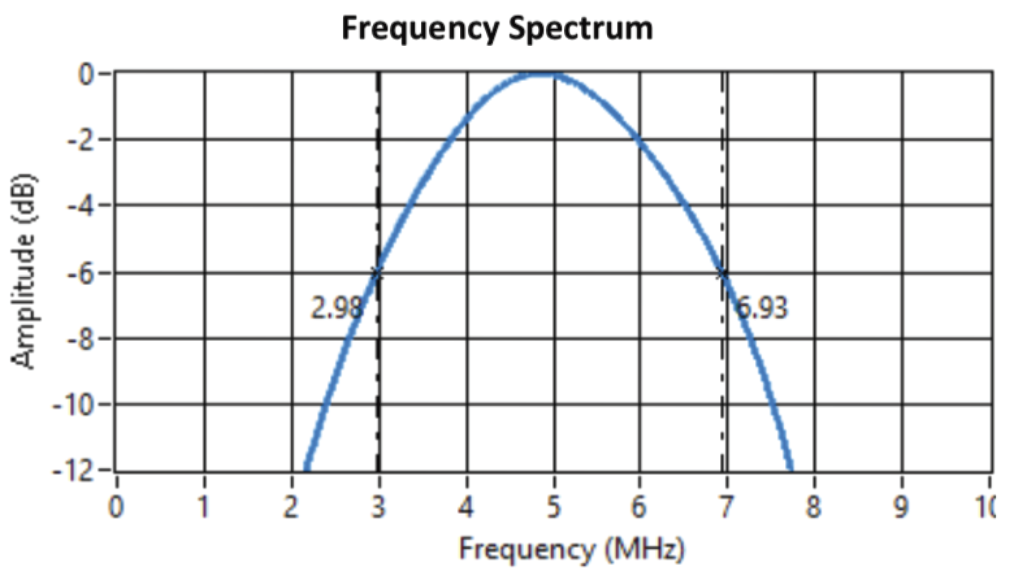

*C Series – Composite (Piezocomposite) Series of transducers have superior sensitivity and penetration especially in highly-attenuative materials. C Series have both higher resolution, sensitivity, and have wide bandwidth (60-120% at -6db) due to the lower acoustic impedance of the material. They couple more efficiently into plastic wedges, delay lines, and water.