SWS

Large Angle-Beam Transducers

Part Numbers

| Frequency (MHz) | Element Dimensions | Part Number | |||

|---|---|---|---|---|---|

| inch | mm | C* | Wedges | Accessories | |

| 0.5 | 0.5 Ø | 12.7 Ø | 00-010478 | 45° 01-010417 | |

| 60° 01-010418 | |||||

| 70° 01-010419 | |||||

| 0.5 x 1 | 12.7 x 25.4 | 00-010479 | 45° 01-010417 | ||

| 60° 01-010418 | Cable | ||||

| 70° 01-010419 | BNC – BNC | ||||

| 0.75 x 1 | 19 x 25.4 | 00-010480 | 45° 01-010417 | 6-ft (1.83 m) | |

| 60° 01-010418 | 07-010018 | ||||

| 70° 01-010419 | |||||

| 1 Ø | 25.4 Ø | 00-010481 | 45° 01-010417 | ||

| 60° 01-010418 | |||||

| 70° 01-010419 | |||||

| 1 | 0.5 Ø | 12.7 Ø | 00-010445 | 45° 01-010417 | |

| 60° 01-010418 | |||||

| 70° 01-010419 | |||||

| 0.5 x 1 | 12.7 x 25.4 | 00-010446 | 45° 01-010417 | ||

| 60° 01-010418 | Cable | ||||

| 70° 01-010419 | BNC – BNC | ||||

| 0.75 x 1 | 19 x 25.4 | 00-010447 | 45° 01-010417 | 6-ft (1.83 m) | |

| 60° 01-010418 | 07-010018 | ||||

| 70° 01-010419 | |||||

| 1 Ø | 25.4 Ø | 00-010448 | 45° 01-010417 | ||

| 60° 01-010418 | |||||

| 70° 01-010419 | |||||

| 2.25 | 0.5 Ø | 12.7 Ø | 00-010449 | 45° 01-010417 | |

| 60° 01-010418 | |||||

| 70° 01-010419 | |||||

| 0.5 x 1 | 12.7 x 25.4 | 00-010450 | 45° 01-010417 | ||

| 60° 01-010418 | Cable | ||||

| 70° 01-010419 | BNC – BNC | ||||

| 0.75 x 1 | 19 x 25.4 | 00-010451 | 45° 01-010417 | 6-ft (1.83 m) | |

| 60° 01-010418 | 07-010018 | ||||

| 70° 01-010419 | |||||

| 1 Ø | 25.4 Ø | 00-010452 | 45° 01-010417 | ||

| 60° 01-010418 | |||||

| 70° 01-010419 | |||||

| 3.5 | 0.5 Ø | 12.7 Ø | 00-010453 | 45° 01-010417 | |

| 60° 01-010418 | |||||

| 70° 01-010419 | |||||

| 0.5 x 1 | 12.7 x 25.4 | 00-010454 | 45° 01-010417 | ||

| 60° 01-010418 | Cable | ||||

| 70° 01-010419 | BNC – BNC | ||||

| 0.75 x 1 | 19 x 25.4 | 00-010455 | 45° 01-010417 | 6-ft (1.83 m) | |

| 60° 01-010418 | 07-010018 | ||||

| 70° 01-010419 | |||||

| 1 Ø | 25.4 Ø | 00-010456 | 45° 01-010417 | ||

| 60° 01-010418 | |||||

| 70° 01-010419 | |||||

| 5 | 0.5 Ø | 12.7 Ø | 00-010457 | 45° 01-010417 | |

| 60° 01-010418 | |||||

| 70° 01-010419 | |||||

| 0.5 x 1 | 12.7 x 25.4 | 00-010458 | 45° 01-010417 | ||

| 60° 01-010418 | Cable | ||||

| 70° 01-010419 | BNC – BNC | ||||

| 0.75 x 1 | 19 x 25.4 | 00-010459 | 45° 01-010417 | 6-ft (1.83 m) | |

| 60° 01-010418 | 07-010018 | ||||

| 70° 01-010419 | |||||

| 1 Ø | 25.4 Ø | 00-010460 | 45° 01-010417 | ||

| 60° 01-010418 | |||||

| 70° 01-010419 |

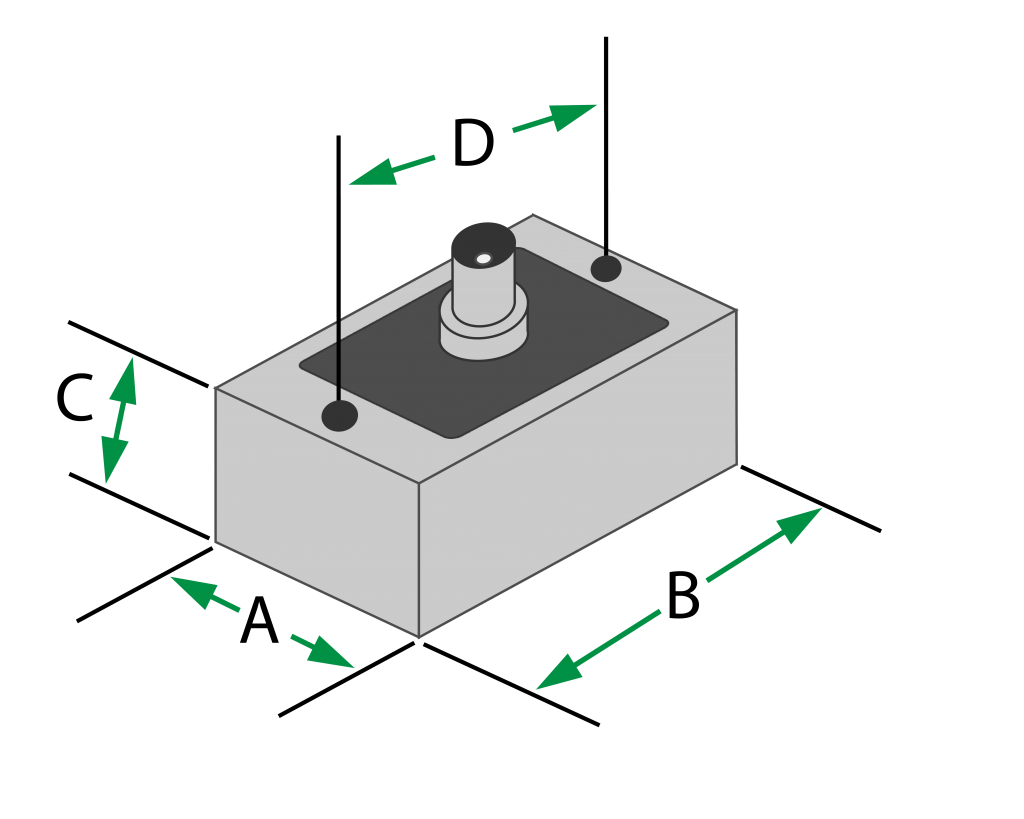

Case Dimensions

| Element Size | A | B | C | D | Thread | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | |||||||||

| 0.5 Ø | 12.7 Ø | 0.72 in. | 18.3 mm | 1.0 in. | 25.4 mm | 0.75 in. | 19.1 mm | 0.81 in. | 20.6 mm | 4-40 |

| 0.5 x 1 | 12.7 25.4 | 0.73 in. | 18.5 mm | 1.5 in. | 38.1 mm | 0.75 in. | 19.1 mm | 1.31 in. | 33.3 mm | 4-40 |

| 0.75 x 1 | 19 x 25.4 | 1.0 in. | 25.4 mm | 1.5 in. | 38.1 mm | 0.75 in. | 19.1 mm | 1.31 in. | 33.3 mm | 4-40 |

| 1 Ø | 25.4 Ø | 1.22 in. | 31 mm | 1.65 in. | 41.9 mm | 0.75 in. | 19.1 mm | 1.38 in. | 35.1 mm | 4-40 |

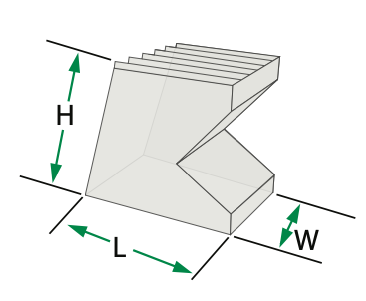

SWS Wedges & Dimensions

| Part Number | Angle | Wedge Dimensions | |||||

|---|---|---|---|---|---|---|---|

| Length | Width | Height | |||||

| 01-010417 | 45° | 1.35 in. | 34.3 mm | 1.1 in. | 30 mm | 1.3 in. | 33 mm |

| 01-010418 | 60° | 1.53 in. | 38.9 mm | 1.1 in. | 30 mm | 1.3 in. | 33 mm |

| 01-010419 | 70° | 1.82 in. | 46.2 mm | 1.1 in. | 30 mm | 1.3 in. | 33 mm |

| 01-010425 | 60° | 1.35 in. | 34.3 mm | 1.6 in. | 40.6 mm | 1.3 in. | 33 mm |

| 01-010426 | 45° | 1.53 in. | 38.9 mm | 1.6 in. | 40.6 mm | 1.3 in. | 33 mm |

| 01-010427 | 60° | 1.82 in. | 46.2 mm | 1.6 in. | 40.6 mm | 1.3 in. | 33 mm |

| 01-010428 | 70° | 2.1 in. | 53.3 mm | 1.5 in. | 38.1 mm | 1.5 in. | 38.1 mm |

| 01-010429 | 60° | 2.3 in. | 48.4 mm | 1.5 in. | 38.1 mm | 1.5 in. | 38.1 mm |

| 01-010430 | 45° | 2.59 in. | 65.8 mm | 1.5 in. | 38.1 mm | 1.5 in. | 38.1 mm |

| 01-010991 | 60° | 2.05 in. | 52.1 mm | 1.65 in. | 41.9 mm | 1.5 in. | 38.1 mm |

| 01-010992 | 70° | 2.24 in. | 56.9 mm | 1.65 in. | 41.9 mm | 1.5 in. | 38.1 mm |

| 01-010993 | 60° | 2.6 in. | 66 mm | 1.65 in. | 41.9 mm | 1.5 in. | 38.1 mm |

SWS Large Angle-Beam Transducers

Model SWS are designed for general weld inspection and other applications such as pipes, tanks, pressure vessels, forgings and castings. They have top mounted BNC connectors and are available with piezocomposite elements (C series*). Interchangeable acrylic wedges provide maximum versatility and service life.

Angle-beam transducers and their wedges generate shear (transverse) waves at the specified angle in a given test material to detect flaws that cannot be detected by a straight-beam transducer. Shear waves are produced by refracting a longitudinal wave in a precision-machined acrylic wedge that also minimizes wedge noise.

Typical Applications

- Weld Inspection

- Tubes and Pipes

- Shafts

- Pressure Vessels

- Turbine Blades

- Forgings and Castings

Series

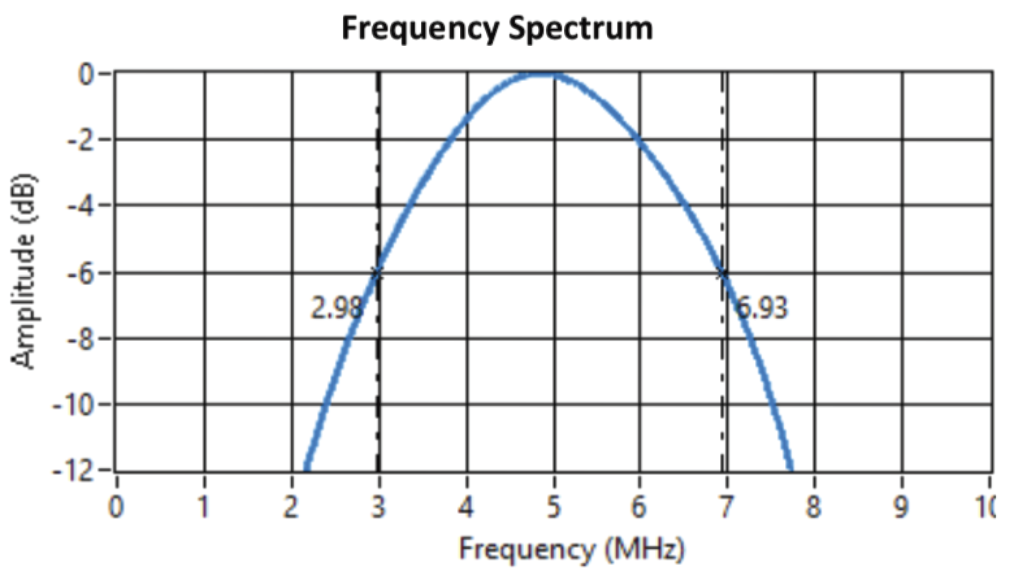

*C Series – Composite (Piezocomposite) Series of transducers have superior sensitivity and penetration especially in highly-attenuative materials. C Series have both higher resolution, sensitivity, and have wide bandwidth (60-120% at -6db) due to the lower acoustic impedance of the material. They couple more efficiently into plastic wedges, delay lines, and water.