MSWS

Small Angle-Beam Transducers

Part Numbers

| Frequency (MHz) | Element Ø inch | Element Ø mm | Part Numbers | Wedges |

|---|---|---|---|---|

| C* | ||||

| 1 | 0.5 | 12.7 | 00-010497 | 45° 01-012776 |

| 60° 01-012777 | ||||

| 70° 01-012778 | ||||

| 2.25 | 0.25 | 6.4 | 00-010498 | 45° 01-012773 |

| 60° 01-012774 | ||||

| 70° 01-012775 | ||||

| 0.5 | 12.7 | 00-010499 | 45° 01-012776 | |

| 60° 01-012777 | ||||

| 70° 01-012778 | ||||

| 3.5 | 0.25 | 6.4 | 00-010500 | 45° 01-012773 |

| 60° 01-012774 | ||||

| 70° 01-012775 | ||||

| 0.5 | 12.7 | 00-010501 | 45° 01-012776 | |

| 60° 01-012777 | ||||

| 70° 01-012778 | ||||

| 5 | 0.25 | 6.4 | 00-010502 | 45° 01-012773 |

| 60° 01-012774 | ||||

| 70° 01-012775 | ||||

| 0.5 | 12.7 | 00-010503 | 45° 01-012776 | |

| 60° 01-012777 | ||||

| 70° 01-012778 | ||||

| 10 | 0.25 | 6.4 | 00-010504 | 45° 01-012773 |

| 60° 01-012774 | ||||

| 70° 01-012775 | ||||

| 0.5 | 12.7 | 00-010505 | 45° 01-012776 | |

| 60° 01-012777 | ||||

| 70° 01-012778 |

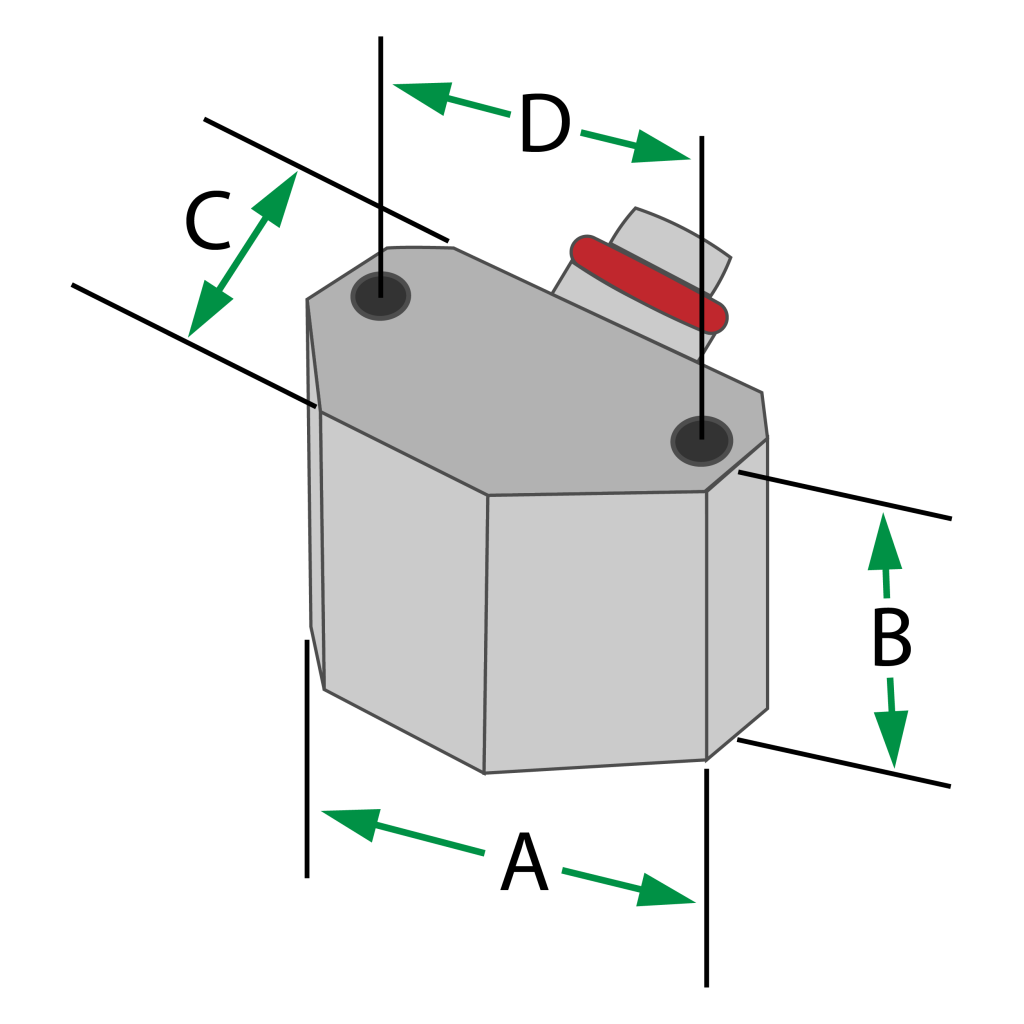

Case Dimensions

| Element Diameter | A | B | C | D | Thread | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | |||||||||

| 0.25 | 6.4 | 0.48 in. | 12.2 mm | 0.34 in. | 8.6 mm | 0.31 in. | 7.9 mm | 0.38 in. | 9.7 mm | 1-64 |

| 0.5 | 12.7 | 0.73 in. | 18.5 mm | 0.5 in. | 12.7 mm | 0.56 in. | 14.2 mm | 0.63 in. | 16 mm | 1-64 |

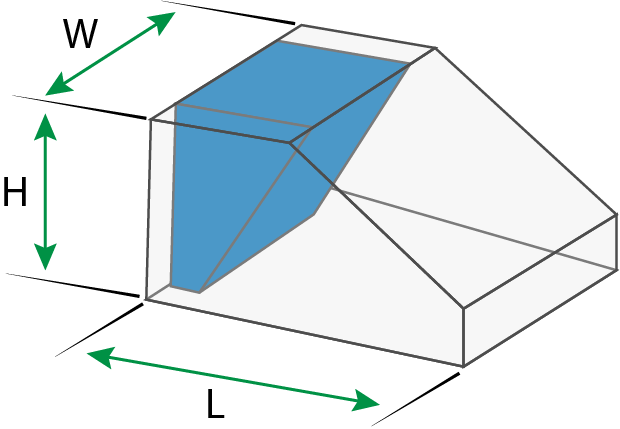

MSWS Wedges & Dimensions

| Part Number | Wedge Degree | Transducer Element Ø | Wedge Dimensions | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Length | Width | Height | |||||||

| 01-012773 | 45° | 0.25 in. | 6.4 mm | 0.59 in. | 15 mm | 0.5 in. | 12.7 mm | 0.26 in. | 6.6 mm |

| 01-012774 | 60° | 0.25 in. | 6.4 mm | 0.65 in. | 16.5 mm | 0.5 in. | 12.7 mm | 0.30 in. | 7.6 mm |

| 01-012775 | 70° | 0.25 in. | 6.4 mm | 0.73 in. | 18.5 mm | 0.5 in. | 12.7 mm | 0.33 in. | 8.4 mm |

| 01-012776 | 45° | 0.5 in. | 12.7 mm | 0.93 in. | 23.6 mm | 0.75 in. | 19 mm | 0.43 in. | 10.9 mm |

| 01-012777 | 60° | 0.5 in. | 12.7 mm | 1.05 in. | 26.7 mm | 0.75 in. | 19 mm | 0.50 in. | 12.7 mm |

| 01-012778 | 70° | 0.5 in. | 12.7 mm | 1.18 in. | 30 mm | 0.75 in. | 19 mm | 0.54 in. | 13.7 mm |

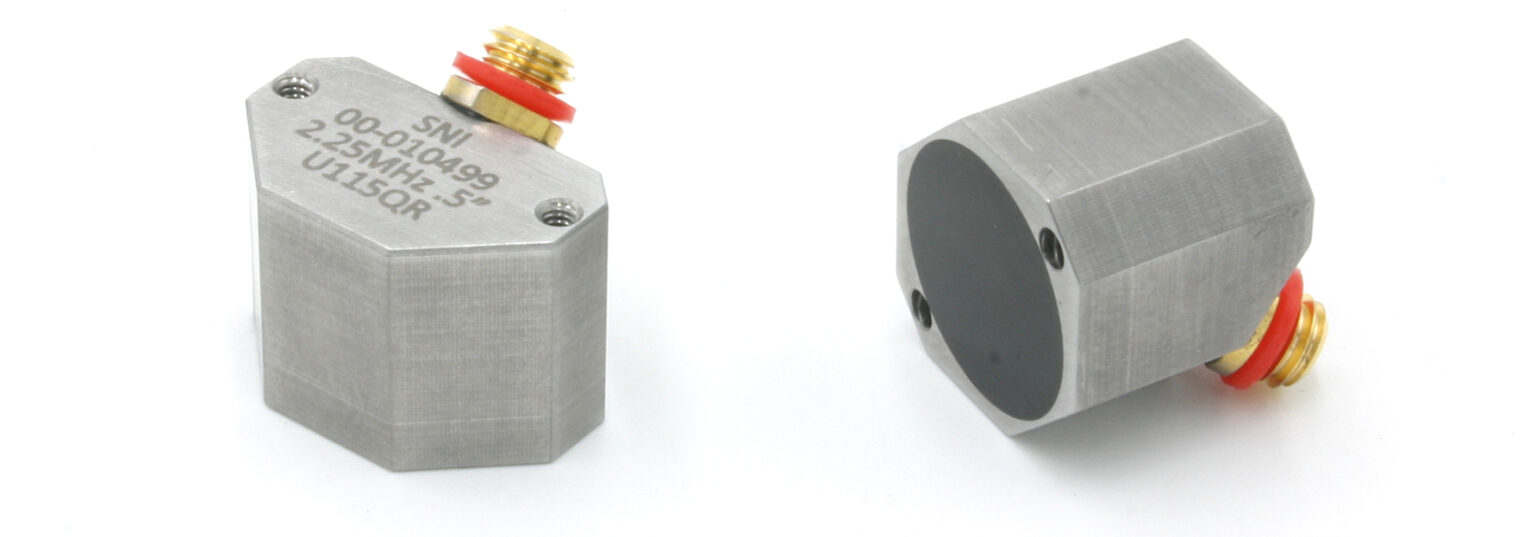

MSWS Small Angle-Beam Transducers

Model MSWS have captive screws for wedge attachment and angled microdot connectors for applications requiring low profile. Piezocomposite (C Series*) offers superior penetration and signal-to-noise ratio in highly attenuative and coarse-grain materials.

Angle-beam transducers and their wedges generate shear (transverse) waves at the specified angle in a given test material to detect flaws that cannot be detected by a straight-beam transducer. Shear waves are produced by refracting a longitudinal wave in a precision-machined acrylic wedge that also minimizes wedge noise.

Typical Applications

- Weld Inspection

- Tubes and Pipes

- Shafts

- Turbine Blades

- Wheel Rims

Key Benefits

- Low profile case allows for access to tight and hard-to-reach areas

- Small contact area allows for inspection of small-diameter pipes and tubes

Series

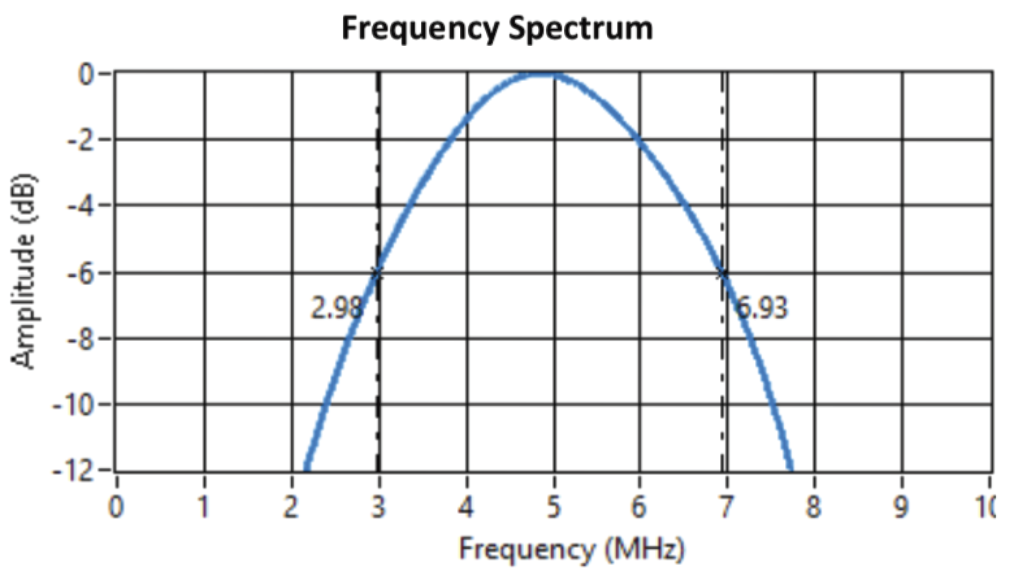

*C Series – Composite (Piezocomposite) Series of transducers have superior sensitivity and penetration especially in highly-attenuative materials. C Series have both higher resolution, sensitivity, and have wide bandwidth (60-120% at -6db) due to the lower acoustic impedance of the material. They couple more efficiently into plastic wedges, delay lines, and water.