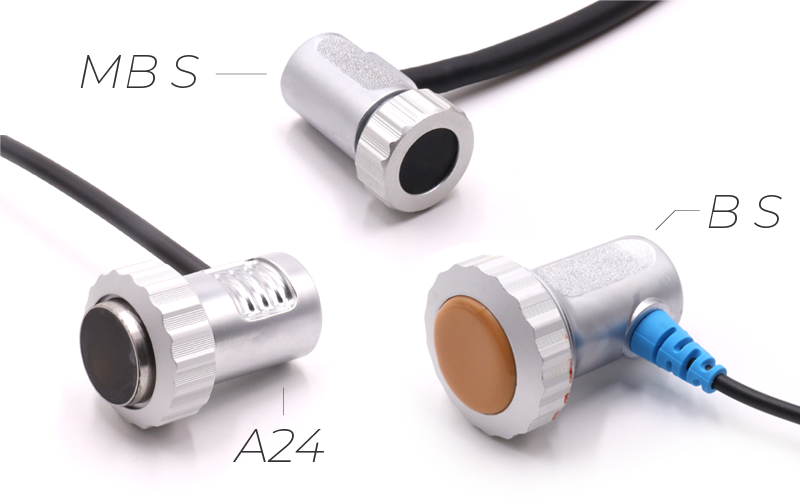

CONTACT MEMBRANE

Linear Contact Membrane Arrays

ADP Transducers

Technology & Features

Resources

ADP Transducers

Part Numbers

| Case | Frequency (MHz) | Number of Elements | Element Pitch | Element Elevation | Part Number | Cable Length | ||

|---|---|---|---|---|---|---|---|---|

| Inch | mm | Inch | mm | GP* | ||||

| A24 | 4 | 16 | 0.040 | 1.00 | 0.63 | 16 | 00-011927 | 2.5M (8.2 ft.) |

| B S | 2 | 16 | 0.060 | 1.50 | 0.94 | 24 | 00-011903 | 2.5M (8.2 ft.) |

| 4 | 16 | 0.060 | 1.50 | 0.94 | 24 | 00-011902 | 2.5M (8.2 ft.) | |

| MB S | 2 | 16 | 0.025 | 0.63 | 0.39 | 10 | 00-011714 | 2.5M (8.2 ft.) |

| 4 | 16 | 0.025 | 0.63 | 0.39 | 10 | 00-011715 | 2.5M (8.2 ft.) |

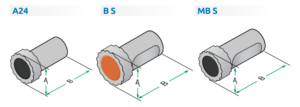

Case Dimensions

| Case Type | Case Dimensions | |||

|---|---|---|---|---|

| A | B | |||

| A24 | 1.07 in. | 27.2 mm | 1.75 in. | 44.5 mm |

| MB S | 0.98 in. | 24.9 mm | 1.61 in. | 40.1 mm |

| B S | 1.77 in. | 45 mm | 2.41 in. | 61.2 mm |

Technology & Features

Linear Contact Membrane Transducers

Contact membrane arrays are linear arrays specially designed and optimized for inspection of threaded bolts or applications with rough surfaces. The membrane allows for effective coupling on those rough surfaces and can be replaced to extend the life of the array. Contact membrane transducers have side-mounted cables but can be special ordered with top-mounted cables.

Typical Applications

- Bolt Inspection

- Rough Surface Inspection

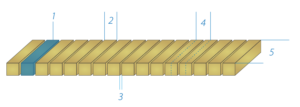

About Linear Arrays

The linear array is the most common form factor used in industrial phased array testing including TFM/FMC applications. The linear array allows electronic control of the active plane of the transducer including steering angle, depth of focus, and position of the sound beam.

- A single element in the array. In this graphic, 1 of 16 elements.

- Width of a single element.

- Space between adjacent elements.

- Array Pitch; the distance between the center points of two adjacent elements. Pitch controls the arrays resolution and steering ability.

- Array Elevation; the length of the elements.

Resources