CR

Contact Transducers

Part Numbers

| Frequency (MHz) | Element Diameter | Part Number | ||

|---|---|---|---|---|

| Inch | mm | GP* | ||

| 1 | 0.5 | 12.7 | 00-010626 | |

| 0.75 | 19 | 00-010901 | ||

| 1 | 25.4 | 00-010902 | ||

| 2.25 | 0.5 | 12.7 | 00-010616 | |

| 0.75 | 19 | 00-010419 | ||

| 1 | 25.4 | 00-010416 | ||

| 3.5 | 0.5 | 12.7 | 00-010903 | |

| 0.75 | 19 | 00-010904 | ||

| 1 | 25.4 | 00-010905 | ||

| 5 | 0.5 | 12.7 | 00-010617 | |

| 0.75 | 19 | 00-010906 | ||

| 1 | 25.4 | 00-010907 | ||

| 10 | 0.5 | 12.7 | 00-010908 | |

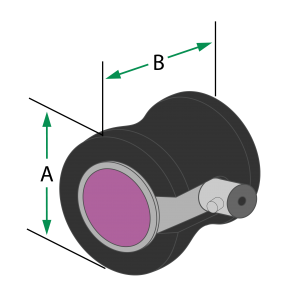

Case Dimensions

| Element Diameter | A | B | ||||||

|---|---|---|---|---|---|---|---|---|

| inch | mm | |||||||

| 0.5 | 12.7 | 1.5 in. | 38.1 mm | 1.3 in. | 33 mm | |||

| 0.75 | 19 | 1.75 in. | 44.5 mm | 1.3 in. | 33 mm | |||

| 1 | 25.4 | 2.0 in. | 50.8 mm | 1.4 in. | 35.6 mm | |||

CR Contact Transducers

The larger element sizes of model CR provide greater scan widths and penetration for applications such as plate, billet, bars, thick-section parts, pipe, and tanks. They have side-mounted BNC connectors and a removable comfort grip to reduce operator fatigue. GP series* offer the best combination of sensitivity and resolution.

Single-element contact transducers are longitudinal-wave (straight-beam) transducers designed for general-purpose manual ultrasonic inspection where test materials are relatively flat and smooth. They provide high sensitivity for better penetration, small-flaw detection, and have abrasion-resistant wear plates for extended service life.

Typical Applications

- Plates

- Billets

- Bars & Pipes

- Thick-Section Parts

- Tanks

Key Benefits

- Large diameter elements allow for efficient scanning of large surfaces

- Abrasion-resistant wear plates for extended service life

- Effective in small-flaw detection

Series

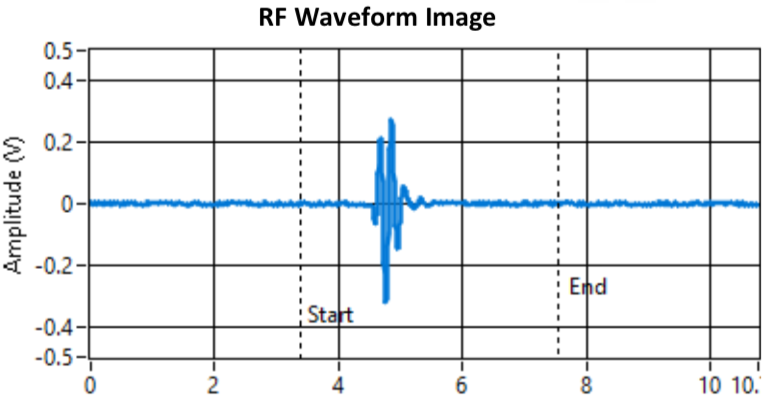

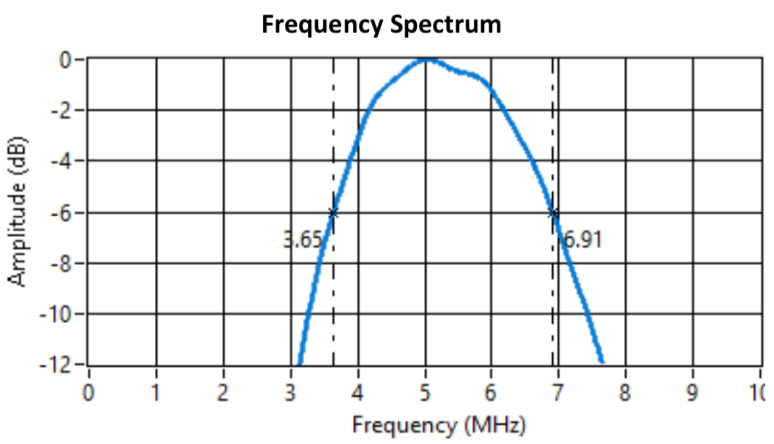

*GP Series – General Purpose series of transducers are recommended for most applications and have a good trade-off between sensitivity and resolution. They have a medium frequency bandwidth of 40-65% at -6db but with more ring-down cycles in the waveform.