AWS

Large Angle beam Transducers

Part Numbers

| Frequency (MHz) | Element Dimensions | Part Number | ||||

|---|---|---|---|---|---|---|

| inch | mm | GP* | C* | Wedges | Accessories | |

| 2.25 | 0.625 x 0.625 | 16 x 16 | 00-010393 | 00-010242 | 45° 01-010414 | |

| 60° 01-010415 | ||||||

| 70° 01-010416 | Cable | |||||

| 0.625 x 0.75 | 16 x 19 | 00-010395 | 00-010394 | 45° 01-010414 | BNC – BNC | |

| 60° 01-010415 | 6-ft (1.83 m) | |||||

| 70° 01-010416 | 07-010018 | |||||

| 0.75 x 0.75 | 19 x 19 | 00-010397 | 00-010396 | 45° 01-010414 | ||

| 60° 01-010415 | ||||||

| 70° 01-010416 |

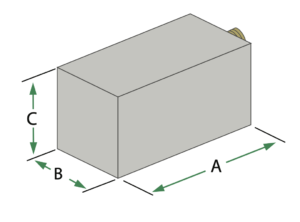

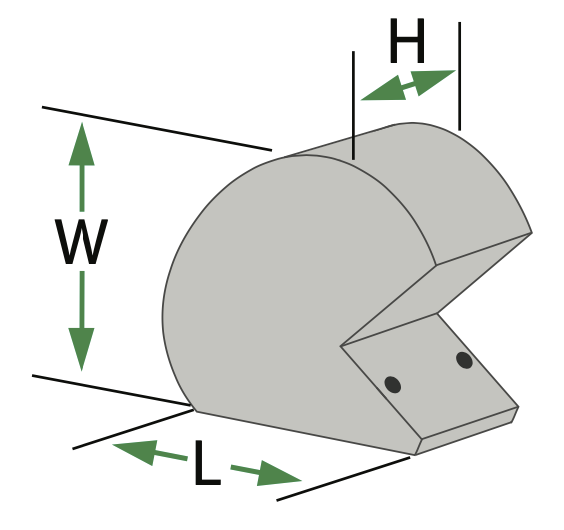

Case Dimensions

| Element Dimensions | A | B | C | D | Thread | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | |||||||||

| 0.625 x 0.625 | 16 x 16 | 0.80 in. | 20.3 mm | 1.26 in. | 32 mm | 0.75 in. | 19.1 mm | 1.0 in. | 25.4 mm | 4-40 |

| 0.625 x 0.75 | 16 x 19 | 0.80 in. | 20.3 mm | 1.26 in. | 32 mm | 0.75 in. | 19.1 mm | 1.0 in. | 25.4 mm | 4-40 |

| 0.75 x 0.75 | 19 x 19 | 0.85 in. | 21.6 mm | 1.26 in. | 32 mm | 0.75 in. | 19.1 mm | 1.0 in. | 25.4 mm | 4-40 |

AWS Wedges & Dimensions

| Part Number | Angle | Wedge Dimensions | |||||

|---|---|---|---|---|---|---|---|

| Length | Width | Height | |||||

| 01-010414 | 45° | 1.82 in. | 46.2 mm | 1.25 in. | 31.8 mm | 1.91 in. | 48.5 mm |

| 01-010415 | 60° | 1.96 in. | 49.8 mm | 1.25 in. | 31.8 mm | 1.91 in. | 48.4 mm |

| 01-010416 | 70° | 2.17 in. | 55.1 mm | 1.25 in. | 31.8 mm | 2.16 in. | 54.9 mm |

AWS Large Angle-Beam Transducers

Model AWS transducers and wedges meet the requirements of American Welding Society Structural Welding Code D1.1 and Bridge Welding Code D1.5. The transducers are available with piezoceramic elements (GP Series*) and piezocomposite elements (C series*)

Angle-beam transducers and their wedges generate shear (transverse) waves at the specified angle in a given test material to detect flaws that cannot be detected by a straight-beam transducer. Shear waves are produced by refracting a longitudinal wave in a precision-machined acrylic wedge that also minimizes wedge noise.

Typical Applications

- Weld Inspection

- Tubes and Pipes

- Shafts

- Turbine Blades

- Wheel Rims

Key Benefits

- Meets the requirements of American Welding Society Structural Welding Code D1.1 and Bridge Welding Code D1.5

- Various available angles and series allow for optimization for different applications

Series

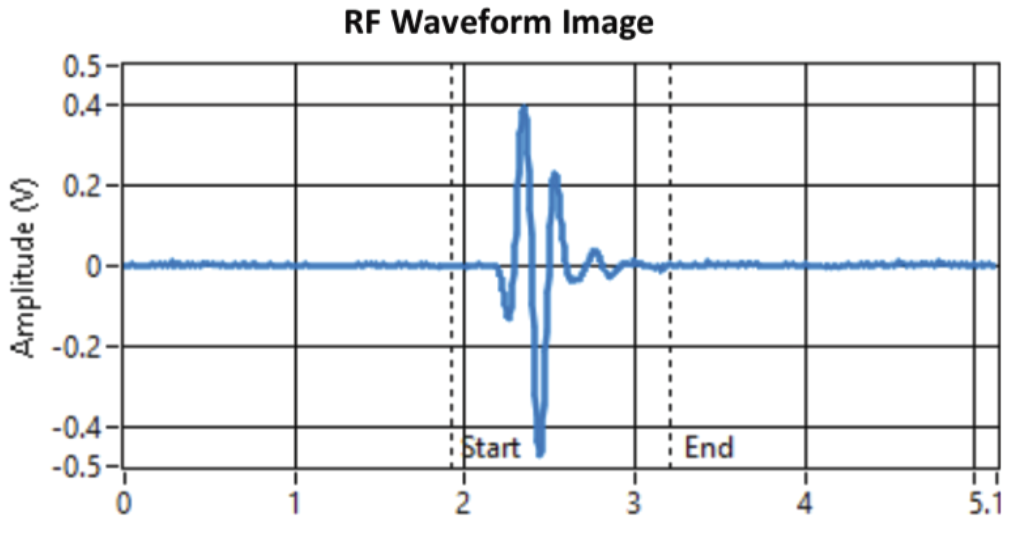

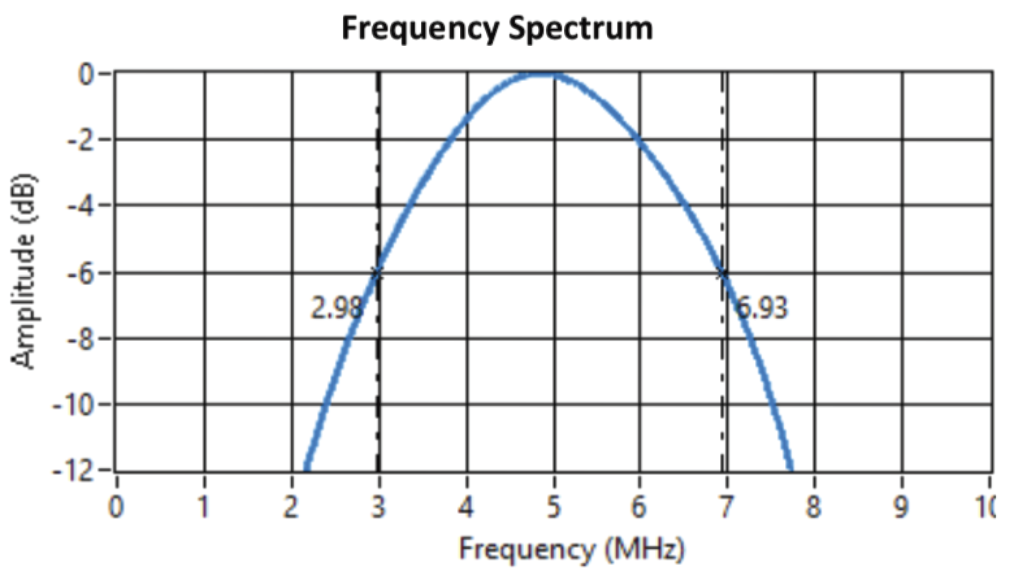

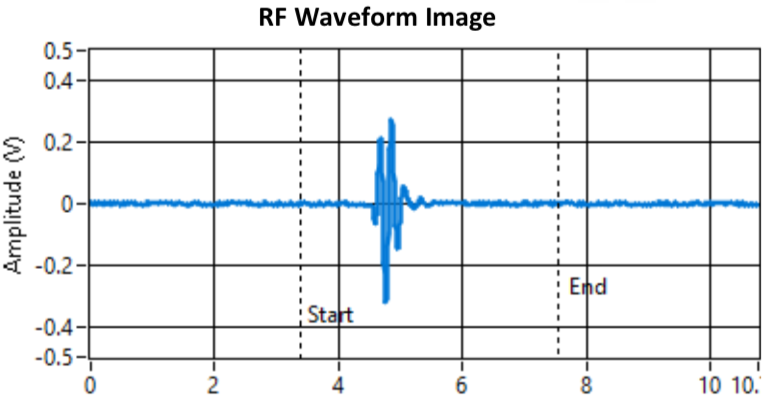

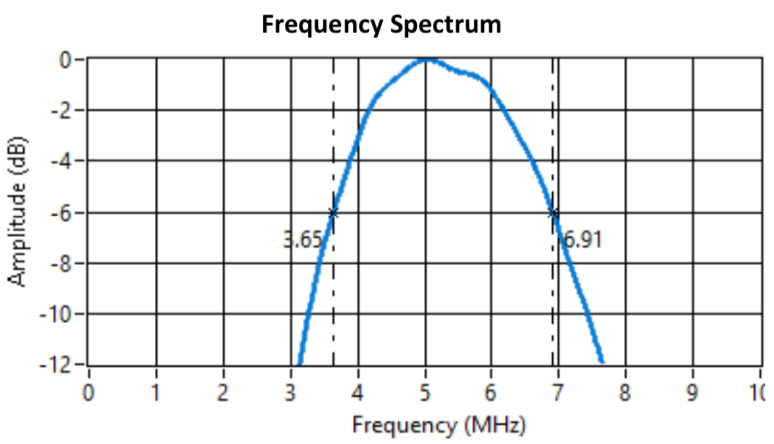

*GP Series – General Purpose Series of transducers are recommended for most applications and have a good trade-off between sensitivity and resolution. They have a medium frequency bandwidth of 40-65% at -6db but with more ring-down cycles in the waveform.

*C Series – Composite (Piezocomposite) Series of transducers have superior sensitivity and penetration especially in highly-attenuative materials. C Series have both higher resolution, sensitivity, and have wide bandwidth (60-120% at -6db) due to the lower acoustic impedance of the material. They couple more efficiently into plastic wedges, delay lines, and water.