MWB+ & MWK+

Integral-Wedge Angle-Beam Transducers

Part Numbers

| Frequency (MHz) | Element Dimensions | Angle (Steel) | Connector Location | Part Number | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | GP* (MWB+) | C* (MWK+) | Accessories | ||||||

| 2 | 0.31 x 0.35 | 8 x 9 | 35 | Top | 00-012227 | 00-012306 | ||||

| Side | 00-012226 | 00-012307 | ||||||||

| 45 | Top | 00-012229 | 00-012308 | |||||||

| Side | 00-012228 | 00-012251 | Cables | |||||||

| 60 | Top | 00-012231 | 00-012309 | |||||||

| Side | 00-012230 | 00-012252 | MD – BNC | |||||||

| 70 | Top | 00-012233 | 00-012310 | Straight | ||||||

| Side | 00-012232 | 00-012253 | 6-ft (1.83 m) | |||||||

| 80 | Top | 00-012235 | 00-012311 | 07-010012 | ||||||

| Side | 00-012234 | 00-012312 | ||||||||

| 90 | Side | 00-012236 | 00-012313 | MCX – BNC | ||||||

| 4 | 0.31 x 0.35 | 8 x 9 | 35 | Top | 00-012238 | 00-012314 | Straight | |||

| Side | 00-012237 | 00-012315 | 6-ft (1.83 m) | |||||||

| 45 | Top | 00-012240 | 00-012316 | 07-010007 | ||||||

| Side | 00-012239 | 00-012248 | ||||||||

| 60 | Top | 00-012242 | 00-012317 | MCX – BNC | ||||||

| Side | 00-012241 | 00-012249 | Right Angle | |||||||

| 70 | Top | 00-012244 | 00-012318 | 6-ft (1.83 m) | ||||||

| Side | 00-012243 | 00-012250 | 07-010008 | |||||||

| 80 | Top | 00-012246 | 00-012319 | |||||||

| Side | 00-012245 | 00-012320 | ||||||||

| 90 | Side | 00-012247 | 00-012321 | |||||||

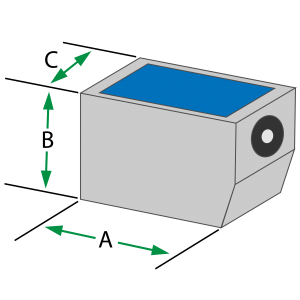

Case Dimensions

| Element Dimensions | A | B | C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | ||||||||||

| 0.31 x 0.35 | 8 x 9 | 1.07 in. | 27.1 mm | 0.86 in. | 21.8 mm | 0.66 in. | 16.8 mm | ||||

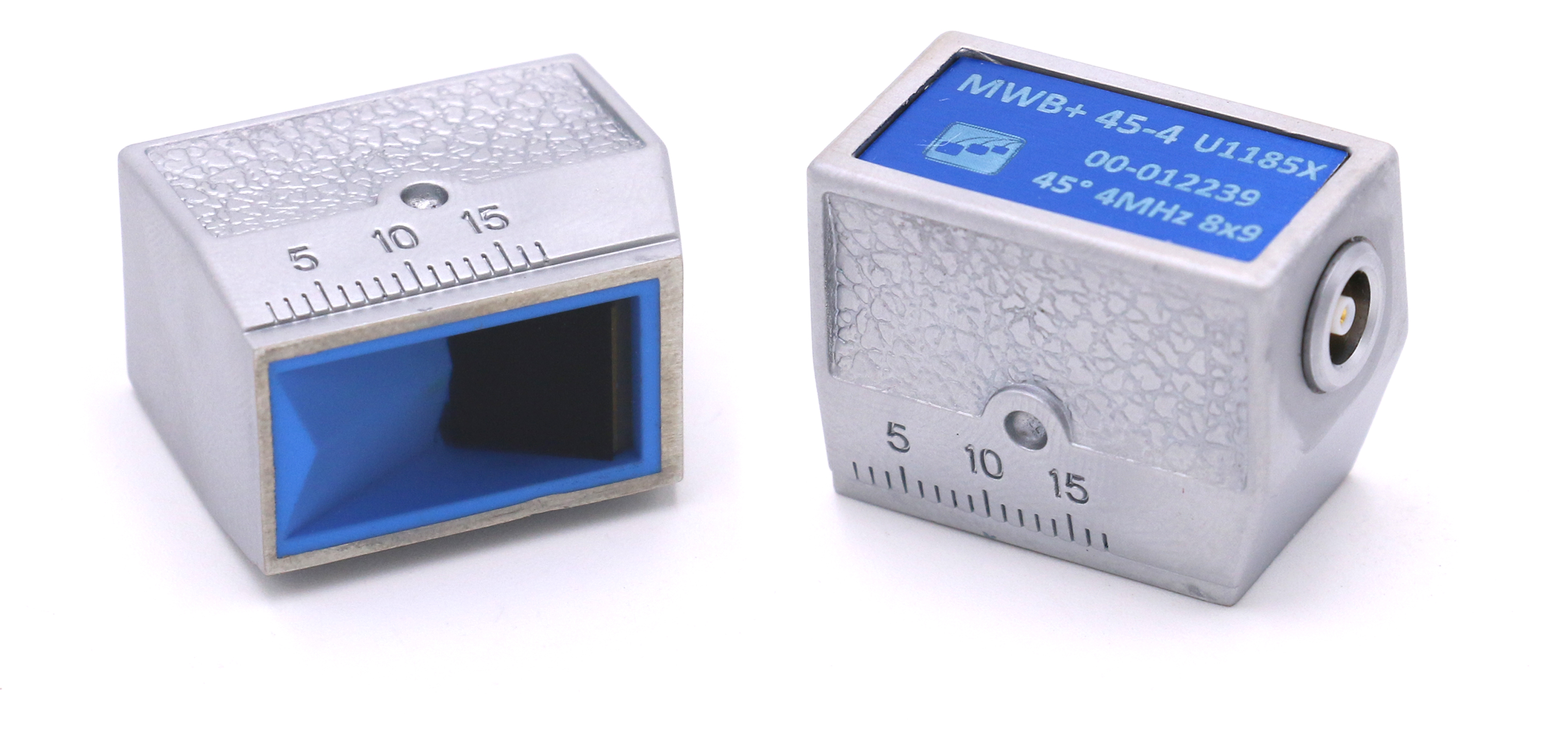

MWB+ & MWK+ Transducers

Models MWB+ and MWK+ are small transducers with side or top-mounted Microdot connectors and integral wedges for maximum versatility. GP series* (MWB+) offer the best combination of sensitivity and resolution. C series* (MWK+) with piezo composite elements offer superior resolution, penetration and signal-to-noise ratio in highly-attenuative and coarse-grain materials such as austenitic stainless steel or cast iron.

Angle-beam transducers and their wedges generate shear (transverse) waves at the specified angle in a given test material to detect flaws that cannot be detected by a straight-beam transducer. Shear waves are produced by refracting a longitudinal wave in a precision-machined acrylic wedge that also minimizes wedge noise.

Typical Applications

- Weld Inspection

- Tubes and Pipes

- Shafts

- Turbine Blades

- Wheel Rims

Series

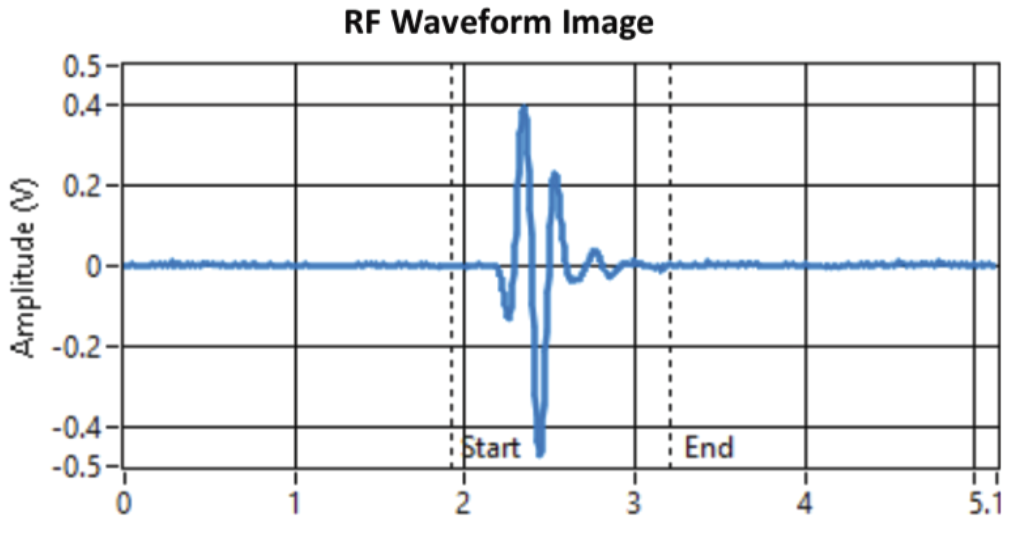

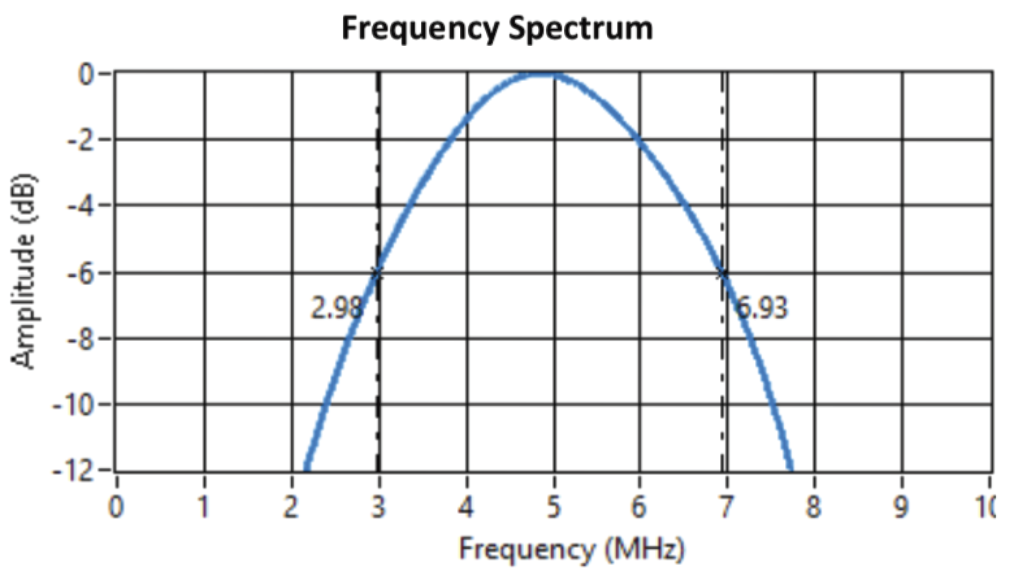

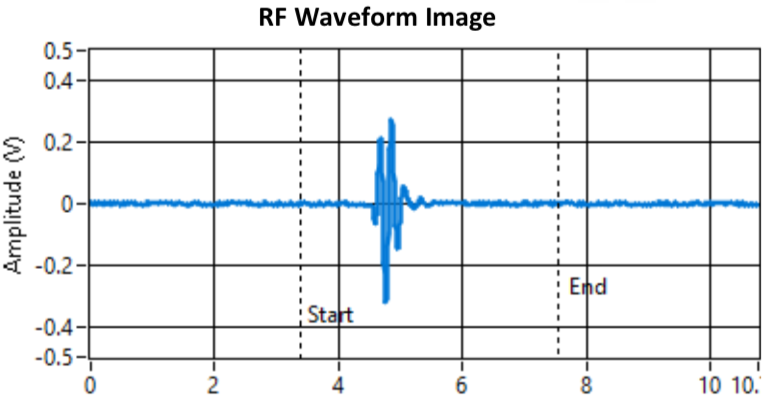

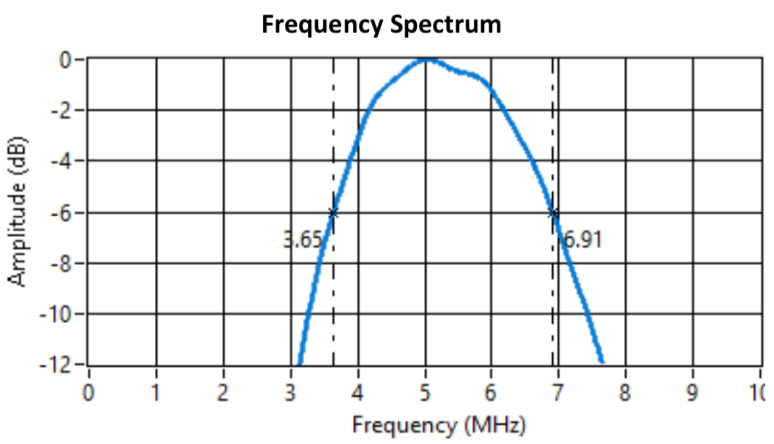

*GP Series – General Purpose Series of transducers are recommended for most applications and have a good trade-off between sensitivity and resolution. They have a medium frequency bandwidth of 40-65% at -6db but with more ring-down cycles in the waveform.

*C Series – Composite (Piezocomposite) Series of transducers have superior sensitivity and penetration especially in highly-attenuative materials. C Series have both higher resolution, sensitivity, and have wide bandwidth (60-120% at -6db) due to the lower acoustic impedance of the material. They couple more efficiently into plastic wedges, delay lines, and water.