FlexArray

Flexible Phased Arrays

FlexArray Transducers

Technology & Features

Resources

FlexArray Transducers

Part Numbers

Processing...

| Frequency (MHz) | Number of Elements | Element Pitch | Elevation | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| Inch | mm | Inch | mm | |||||

| 5 | 64 | 0.04 | 1 | 0.28 | 7 | 00-012703 | ||

| 7 | 64 | 0.04 | 1 | 0.28 | 7 | 00-012975 | ||

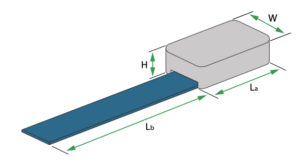

Case Dimensions

Processing...

| Case Dimensions | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| La | H | W | Lb | |||||||||||

| 2.57 in. | 65.3 mm | 0.64 in. | 16.3 mm | 1.27 in. | 32.3 mm | 4.7 in. | 119.4 mm | |||||||

Technology & Features

FlexArray Transducers

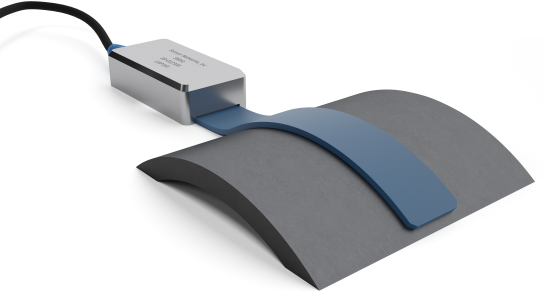

Flexible arrays are perfect for applications on curved metals and composites and can flex to fit a wide range of radii. Flexible arrays improve the inspection on complex geometry by reducing distortion and loss of sensitivity created by complex coupling requirements. Sensor Networks’ flexible arrays are designed to meet the needs of various complex inspections with increased flaw detection and quicker inspection time.

Typical Applications

- Inspection of complex geometries

- Flaw Detection of large surfaces

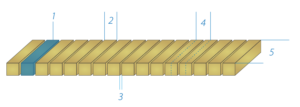

About Linear Arrays

The linear array is the most common form factor used in industrial phased array testing including TFM/FMC applications. The linear array allows electronic control of the active plane of the transducer including steering angle, depth of focus, and position of the sound beam.

- A single element in the array. In this graphic, 1 of 16 elements.

- Width of a single element.

- Space between adjacent elements.

- Array Pitch; the distance between the center points of two adjacent elements. Pitch controls the arrays resolution and steering ability.

- Array Elevation; the length of the elements.

Resources