High-Temperature

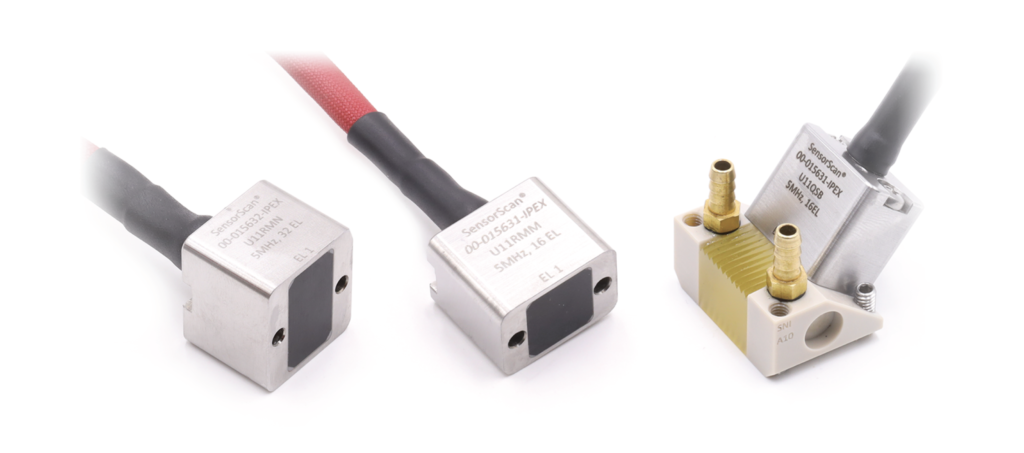

UT flaw detection transducers

Phased-Array

Time-Of-Flight

Diffraction

Dual-Linear

Corrosion

Arrays

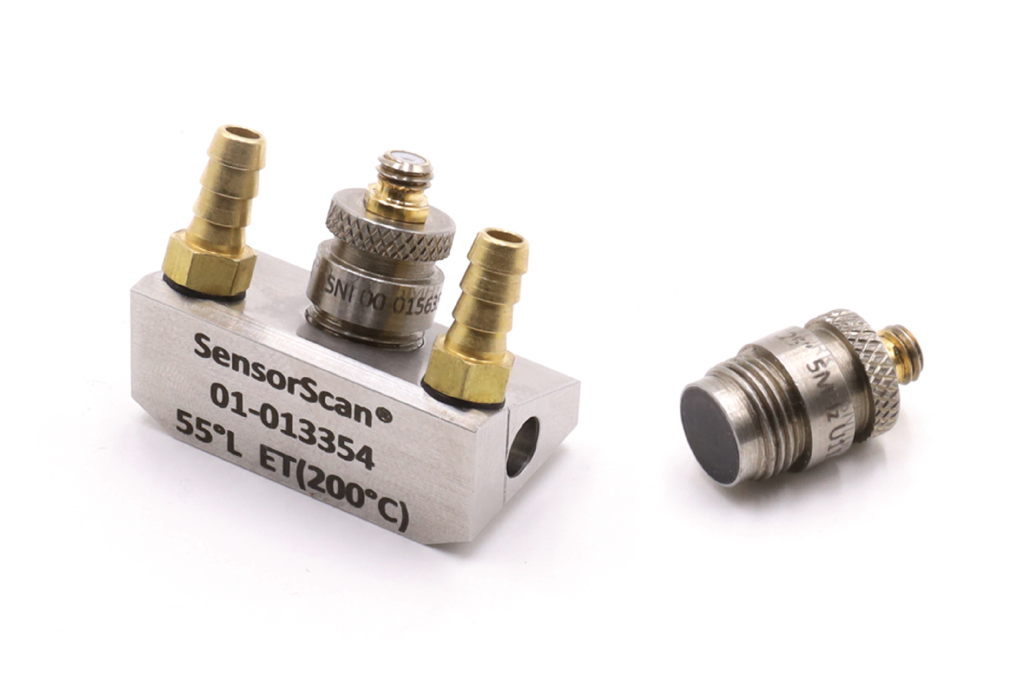

Wedges

Covering flaw scanning and sizing from standard to elevated temperatures all in one transducer

If you’re inspecting or planning to perform on-line, elevated temperature flaw detection using linear phased-array, TOFD or dual-linear arrays for corrosion detection and mapping, SNI has a better solution for you. We have developed and done extensive testing on a family of PAUT arrays, transducers, and wedges that can operate at up to 200°C (392°F) continuous metal-surface temperatures.

Changes in the transducers and the wedge’s resultant refracted angle, due to temperature change, is predictable and can be managed and compensated for in the calibration process. The attached data shows the temperature effects on both attenuation, frequency, velocity, and refracted angle. The new transducer designs are engineered with materials capable of transitioning and operating at these higher temperatures associated with on-line Oil & Gas and Power Gen applications thereby enabling the inspection and protecting the user’s investment in the various transducers.